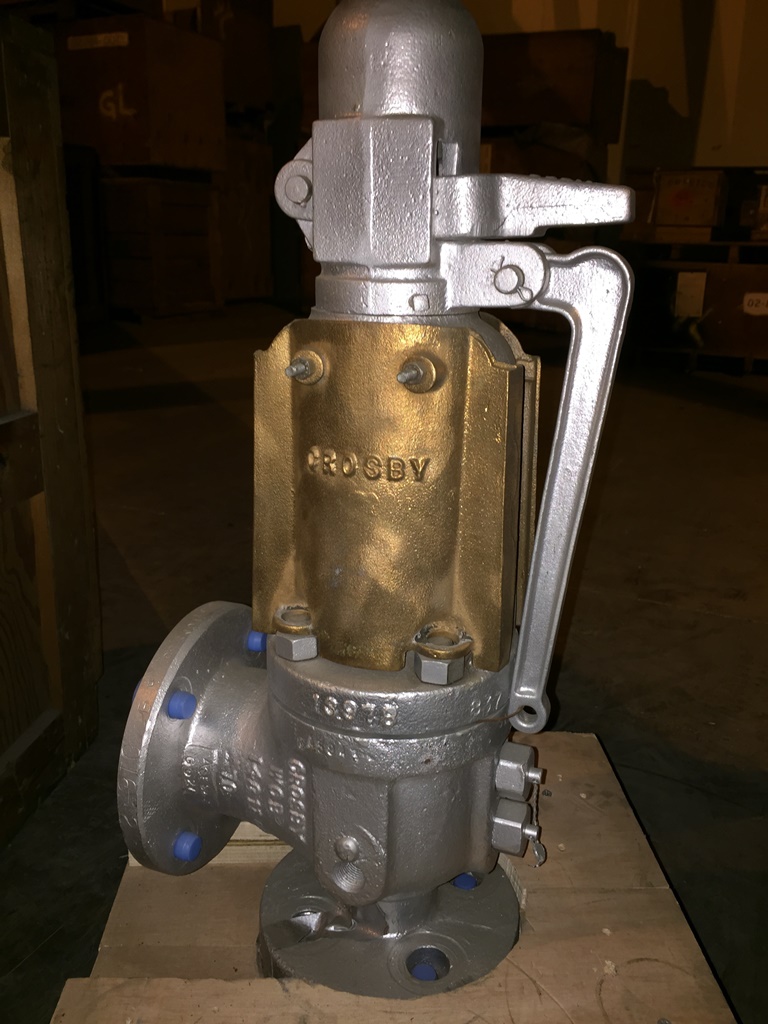

Crosby Safety Valve

Crosby Safety Valve - Web crosby safety relief valves. Set and tested on steam. Asme/nb certified capacities for steam. Interchangeable parts to reduce maintenance costs. Crosby is part of emerson’s pressure relief portfolio, a complete range of standard and customized solutions, whatever need you have for overpressure protection. Direct spring safety valves that provide comprehensive overpressure protection for asme boiler and pressure vessel code section i, and section viii steam safety applications.

Series hsj is a full nozzle reaction type safety valve designed for saturated and superheated steam service on drums, superheater outlets, reheater inlets and outlets and economizer applications. Web crosby safety relief valves. Web ensured balanced operation after bellows rupture enhances safety. Crosby h series direct spring safety valves. Restricted lift for customized capacity.

Isoflex seat tightness up to 93%. Restricted lift for customized capacity. Web pressure and safety relief valves. • full nozzle flanged option. Set and tested on steam.

Over 90% reduction of leakage through bonnet vent. Full compliance with all major global pressure relief standards including asme viii, xiii, api 526/527, en4126 and ped/ce. Interchangeable parts to reduce maintenance costs. Set and tested on steam. • full nozzle flanged option.

• restricted lift for customized capacity. Restricted lift for customized capacity. Series hsj is a full nozzle reaction type safety valve designed for saturated and superheated steam service on drums, superheater outlets, reheater inlets and outlets and economizer applications. • set and tested on steam. • isoflex seat tightness up to 93%.

Before installation these instructions must be fully read and understood. Crosby® pressure relief spring engineering handbook Set and tested on steam. • isoflex seat tightness up to 93%. Crosby h series direct spring safety valves.

Full compliance with all major global pressure relief standards including asme viii, xiii, api 526/527, en4126 and ped/ce. Direct spring safety valves that provide comprehensive overpressure protection for asme boiler and pressure vessel code section i, and section viii steam safety applications. Web crosby h series direct spring safety valves. Web learn about the crosby hci series direct spring safety.

Crosby Safety Valve - Asme/nb certified for air, water and steam. The design is suitable for set pressures to 725 psig (50 barg) and temperatures to 1000°f (538°c), with high capacities, two choices of inlet flange ratings and simplicity of design to facilitate ease of maintenance. Web learn about the crosby hci series direct spring safety valve. • full nozzle flanged option. Visit emerson.com for more details. Crosby h series direct spring safety valves.

Interchangeable parts to reduce maintenance costs. • full nozzle flanged option. Crosby h series direct spring safety valves. Web crosby h series direct spring safety valves. Asme/nb certified capacities for steam.

Isoflex Seat Tightness Up To 93%.

Web crosby safety relief valves. Restricted lift for customized capacity. The design is suitable for set pressures to 725 psig (50 barg) and temperatures to 1000°f (538°c), with high capacities, two choices of inlet flange ratings and simplicity of design to facilitate ease of maintenance. Direct spring safety valves that provide comprehensive overpressure protection for asme boiler and pressure vessel code section i, and section viii steam safety applications.

Set And Tested On Steam.

• restricted lift for customized capacity. Crosby h series direct spring safety valves. • full nozzle flanged option. Web ensured balanced operation after bellows rupture enhances safety.

Web Pressure Relief & Safety Valves.

Crosby is part of emerson’s pressure relief portfolio, a complete range of standard and customized solutions, whatever need you have for overpressure protection. Web crosby h series direct spring safety valves. • isoflex seat tightness up to 93%. • set and tested on steam.

Before Installation These Instructions Must Be Fully Read And Understood.

Full compliance with all major global pressure relief standards including asme viii, xiii, api 526/527, en4126 and ped/ce. • set and tested on steam. Interchangeable parts to reduce maintenance costs. Asme/nb certified capacities for air, water and steam.