Driveline Angle Worksheet

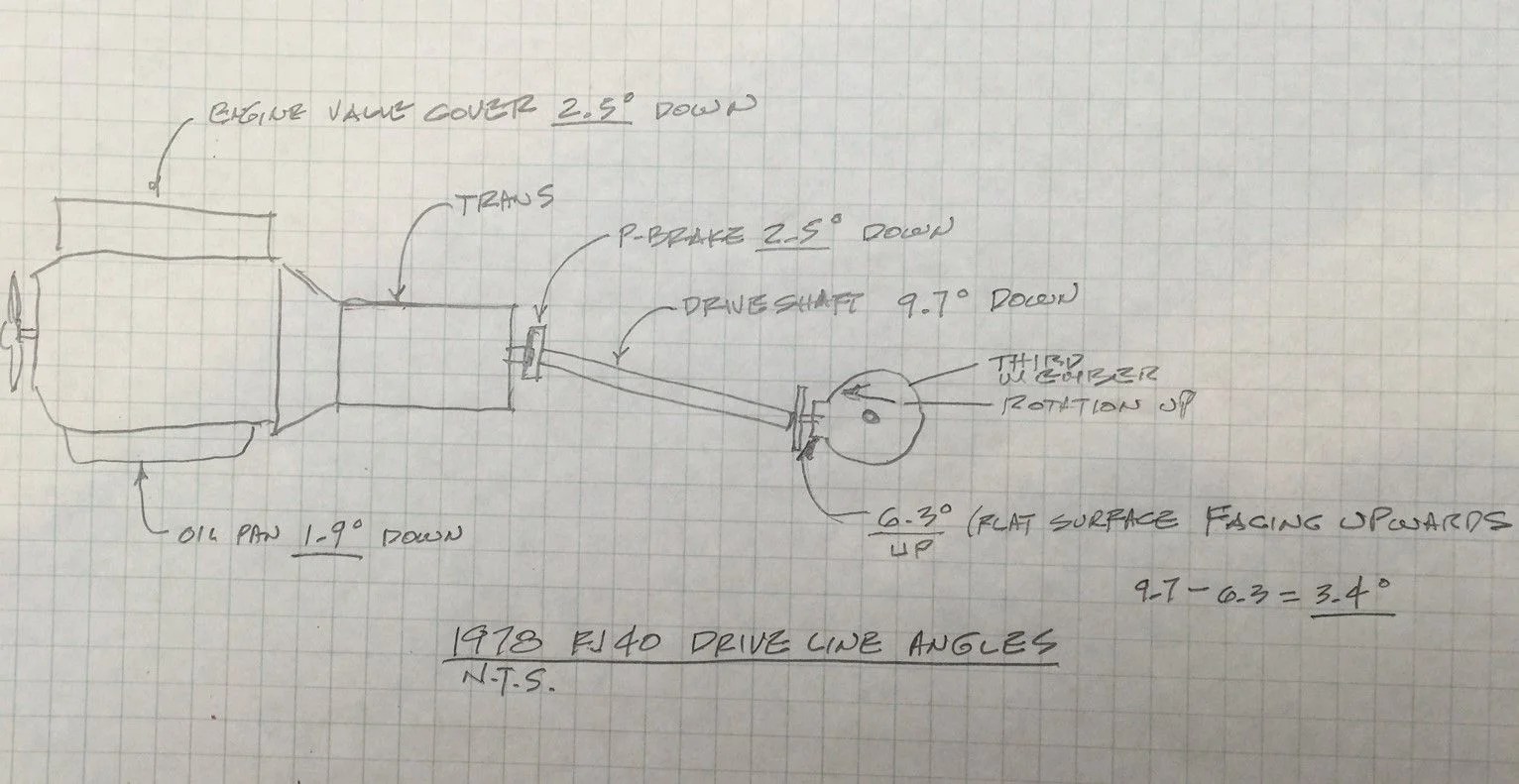

Driveline Angle Worksheet - Read and understand all instructions and procedures before you begin to service components. Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. Enhance your vehicle's performance with our driveline angle guide. Tools you’ll need • an inclinometer or a spirit level protractor to measure driveline angles • a tape measure to measure ride height for. This video offers a quick tutorial that can makes measuring driveline angles a snap. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down).

Correct universal joint operating angles are crucial in preventing torsional and inertial effects, which create vibrations that can damage many of the driveline components in your vehicle. Measure and record main driveline angles. Select the number of shafts in your application. Enhance your vehicle's performance with our driveline angle guide. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull!

If the coupling angle of the shaft exceeds 3.0°, the life of the universal joint. Tools you’ll need • an inclinometer or a spirit level protractor to measure driveline angles • a tape measure to measure ride height for. Measure and record main driveline angles. The optimal angle for any driveshaft to run at is 1/2 degree, where many. Operating.

If the coupling angle of the shaft exceeds 3.0°, the life of the universal joint. Select the number of shafts in your application. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! Specifically we are focusing on drive shaft angle on lifted trucks and jeeps. For each of the following values,.

Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! For each of the following values,. Printable worksheets to aide in collecting the needed driveline measurements. The optimal angle for any driveshaft to run at is 1/2 degree, where many. Measure and record main driveline angles.

Enhance your vehicle's performance with our driveline angle guide. Select the number of shafts in your application. This 101 course will help you measure and correct your driveline. Read and observe all warning and caution hazard alert messages in this publication. Tools you’ll need • an inclinometer or a spirit level protractor to measure driveline angles • a tape measure.

For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Enhance your vehicle's performance with our driveline angle guide. Read if you want to fully understand why drive line geometry is important and how it affects the type of shaft. This video offers a quick tutorial that can makes measuring driveline angles.

Driveline Angle Worksheet - Enhance your vehicle's performance with our driveline angle guide. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! Read and understand all instructions and procedures before you begin to service components. Read if you want to fully understand why drive line geometry is important and how it affects the type of shaft. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Read and observe all warning and caution hazard alert messages in this publication.

This video offers a quick tutorial that can makes measuring driveline angles a snap. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! The optimal angle for any driveshaft to run at is 1/2 degree, where many. Specifically we are focusing on drive shaft angle on lifted trucks and jeeps. Select the number of shafts in your application.

This 101 Course Will Help You Measure And Correct Your Driveline.

If the coupling angle of the shaft exceeds 3.0°, the life of the universal joint. Select the number of shafts in your application. + _ length(in) to measure driveline length: Correct universal joint operating angles are crucial in preventing torsional and inertial effects, which create vibrations that can damage many of the driveline components in your vehicle.

Read And Understand All Instructions And Procedures Before You Begin To Service Components.

Select the number of shafts in your application. Enhance your vehicle's performance with our driveline angle guide. This video offers a quick tutorial that can makes measuring driveline angles a snap. Printable worksheets to aide in collecting the needed driveline measurements.

For Each Of The Following Values,.

Select the number of shafts in your application. Imbedded support for many commonly used driveshaft and axle models (35 driveshaft models, 53 single axle. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). The optimal angle for any driveshaft to run at is 1/2 degree, where many.

Read If You Want To Fully Understand Why Drive Line Geometry Is Important And How It Affects The Type Of Shaft.

Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. Specifically we are focusing on drive shaft angle on lifted trucks and jeeps. Measure and record main driveline angles. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull!